The Challenge

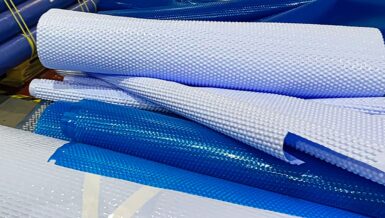

As part of their recycling process, Parry and Evans shred their paper reels, cores, and paper bundles to reduce the volume of the material. This enables them to produce denser bales and reduce transportation costs.

As part of an investment in the best equipment, Parry and Evans required a new shredder that was easier to maneuver around the site and could provide them with increased throughputs to increase their production capacity, and to save on operational costs.

The Solution

Following a series of meetings and site visits, CRJ was able to establish the specific requirements that a new shredder needed to meet.

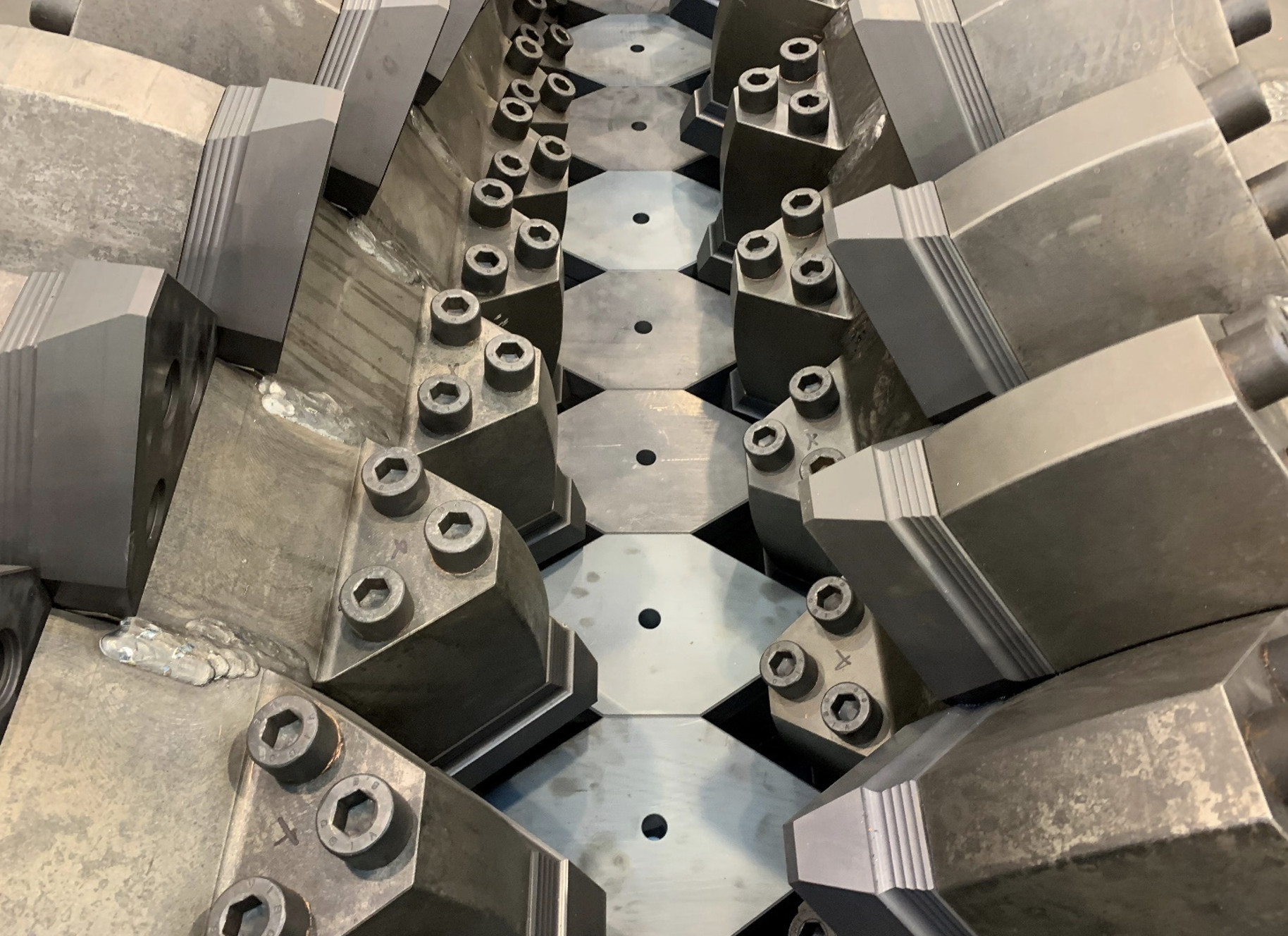

CRJ suggested the HAAS TYRON 2000 XL 2.0 would be able to significantly boost their throughput tonnages thanks to its independently driven twin shaft configuration, and large tilting hopper that provides an aggressive infeed. The hopper also comes equipped with foldable extensions which further increase the size of the infeed area which is ideal for the long cardboard tubes present in this specific application.

The HAAS TYRON is fitted with crawler tracks for easy maneuverability around the site and to seamlessly move the shredder from one application to another.

Why was the HAAS TYRON chosen over other options?

We felt the machine was well built, and as a company, we knew what CRJ services are like due to previous rentals.

What have been the main benefits of operating the Tyron over previous shredders?

It has a large hopper, great throughput, is self-cleaning and the service backup from CRJ is excellent.

What increase in throughput have you seen from the new shredder?

In comparison to our previous shredder, Tyron is achieving an additional 50% throughput.