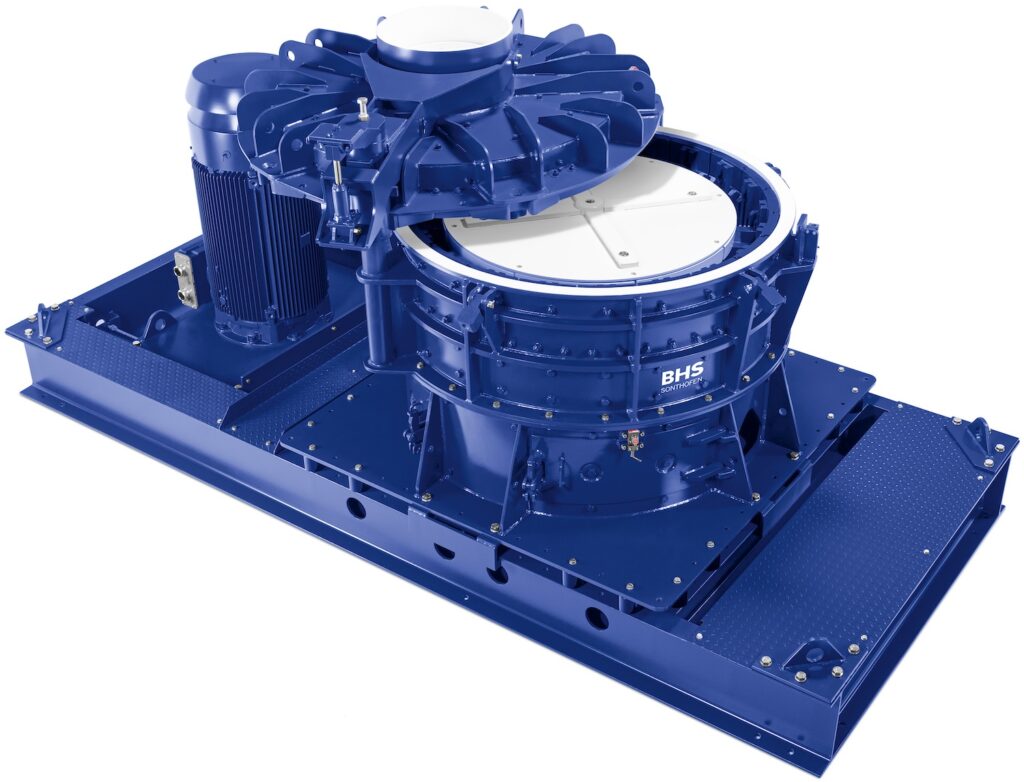

Battery recycling varies by type due to the diverse chemistries involved. Lithium-ion batteries, prevalent in electronics and EVs, are disassembled, shredded, and thermally treated to retrieve lithium, cobalt, and nickel. Lead-acid batteries, common in vehicles, are crushed, with lead and plastic separated for reprocessing. Nickel-cadmium batteries are treated with smelting methods to reclaim metals like nickel and cadmium. Alkaline batteries, used in household devices, undergo mechanical processing to recover steel, zinc, and manganese.

Each recycling process aims to extract valuable materials, reduce environmental impact, and promote sustainability. However, challenges like toxicity and complex chemistries make achieving 100% recycling difficult. Advances in technology and growing environmental concerns drive ongoing improvements in battery recycling methods for a more circular and resource-efficient future.

Lead–acid batteries

Lead-acid battery recycling involves several steps to recover valuable materials and prevent environmental harm. The batteries are collected and crushed to separate plastic and lead components. The plastic is recycled, while the lead is melted and purified. This purified lead can then be used to manufacture new batteries. The recycling process helps conserve resources, reduce the demand for raw materials, and prevent lead pollution. Proper lead-acid battery recycling is crucial due to the toxic nature of lead, ensuring that it is safely managed and reused in an environmentally responsible manner.

Silver oxide batteries

Silver oxide batteries, commonly found in watches and medical devices, can be recycled to recover valuable silver and other materials. The recycling process involves collecting and disassembling the batteries, separating the silver oxide content from other components. Chemical methods are employed to extract the silver, which can be reused in various industries. Proper recycling of silver oxide batteries helps conserve precious metals and prevents environmental contamination. However, due to the specialized nature of these batteries, recycling facilities may be limited, underscoring the importance of supporting proper disposal and recycling practices for these specific battery types.

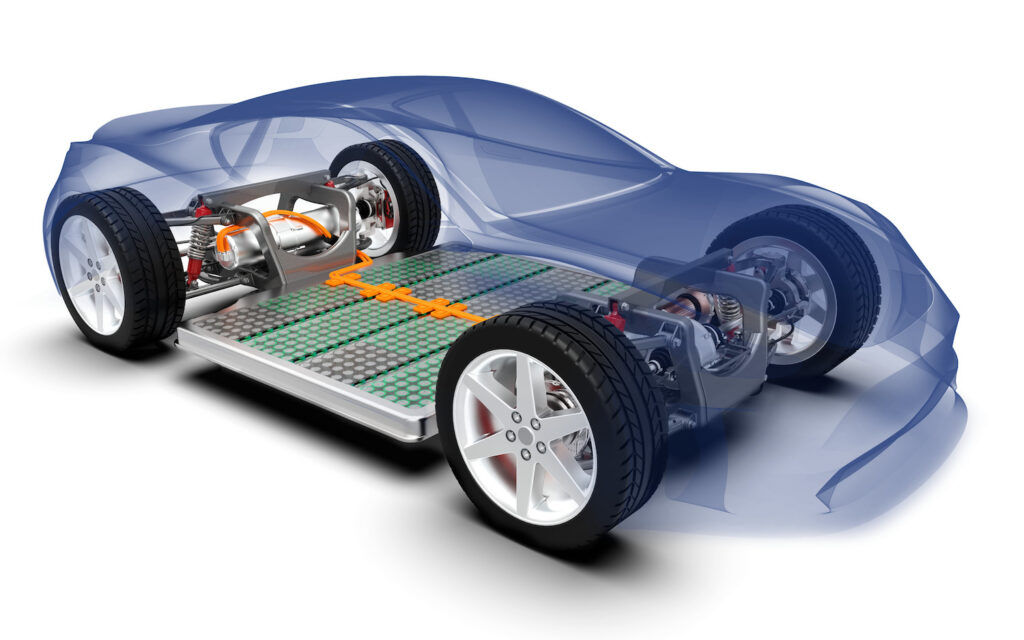

Lithium ion batteries

Lithium-ion battery recycling is a multi-step process aimed at reusing valuable materials and minimizing environmental impact. The batteries are collected, discharged, and mechanically crushed into smaller pieces. Chemical or high-temperature processes are then used to extract lithium, cobalt, nickel, and other metals. These materials are refined for use in manufacturing new batteries or other products. Recycling lithium-ion batteries reduces the need for raw material mining, conserves resources, and prevents hazardous waste. The growing demand for electric vehicles and electronics underscores the significance of efficient lithium-ion battery recycling to create a more sustainable and resource-efficient future.